Oring groove design considerations and engineering guides for static face seals, metric orings, static dovetail orings, static rodpiston orings and dynamic rodpiston orings Find the right oring groove design and easily order your oring online from An engineering design flaw in the Oring seal on one of the solid rocket boosters caused a leak of hot gas that eroded the external fuel tank and led to the explosion The leak was exacerbated by unusually cold weather the night before the launch, which caused the Oring to lose elasticity and form a bad seal Almost no one realized that this might be a problem until itCreated Date AM

O Ring Groove Design Sealing Australia

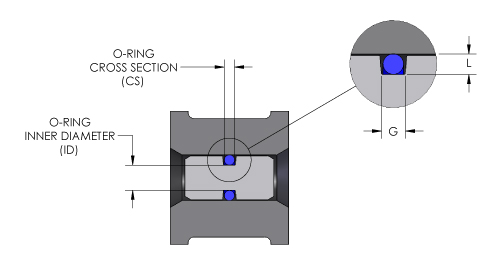

O-ring axial seal design

O-ring axial seal design-Rubber Seals, Sealing Devices & ORing Seal Design AppleO'ring Groove Design As important as the o'ring seal itself is the groove that the o'ring seats into The groove must be designed to accommodate not just the o'ring size, but also its intended usage;

Seals Eastern End Cap O Ring Seal Design Guideline

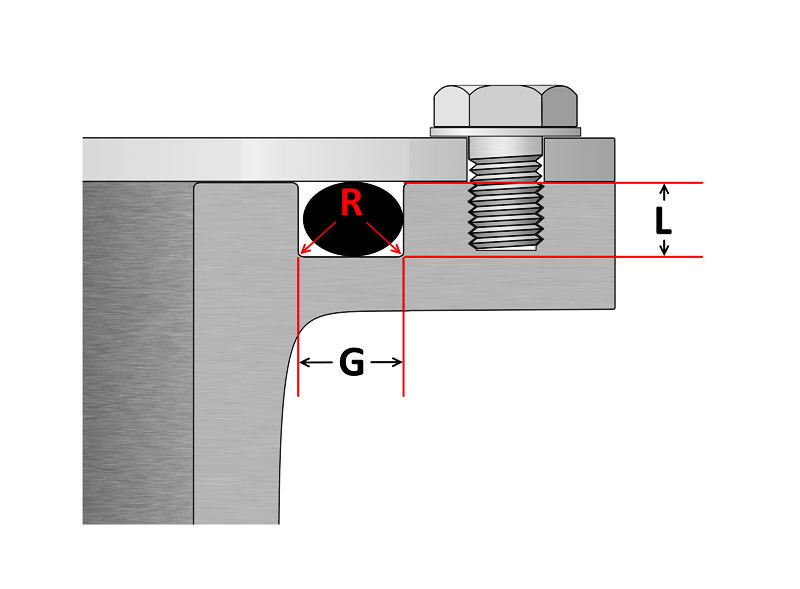

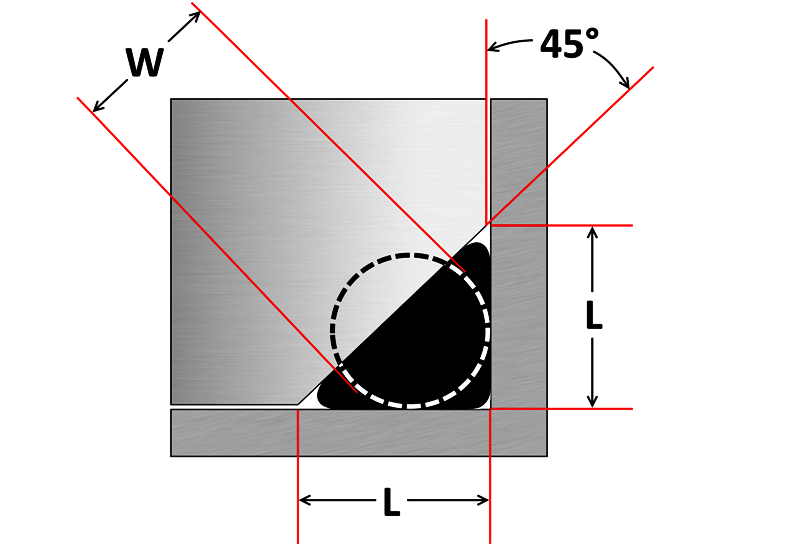

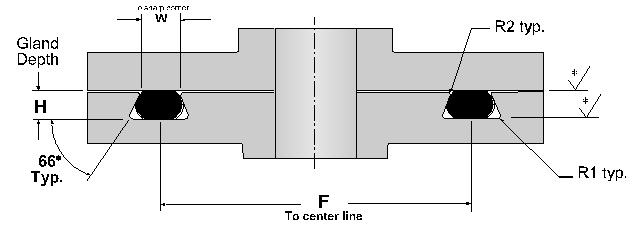

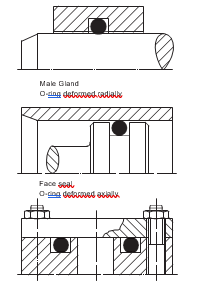

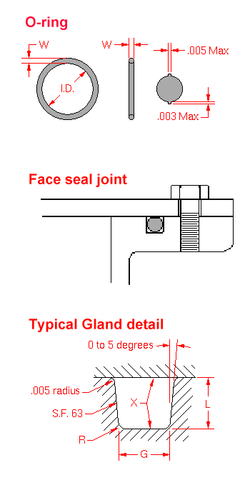

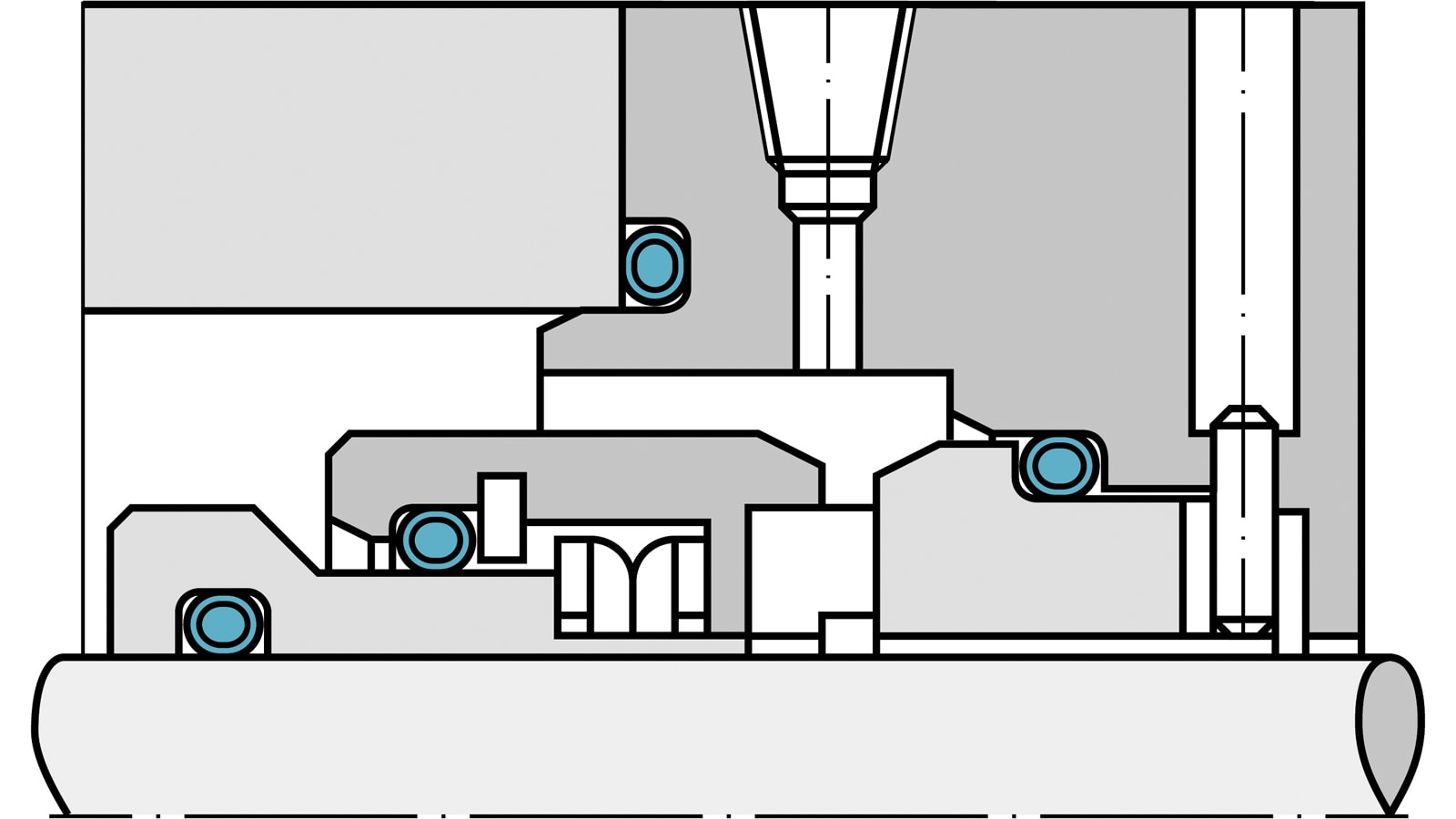

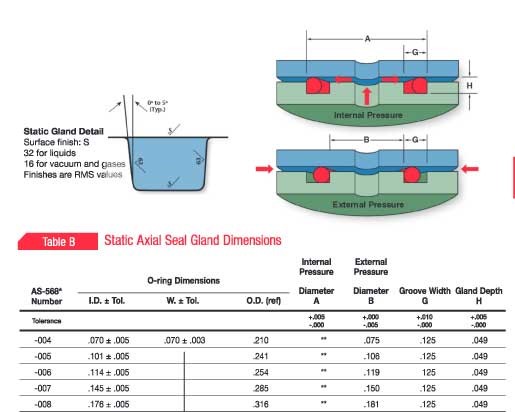

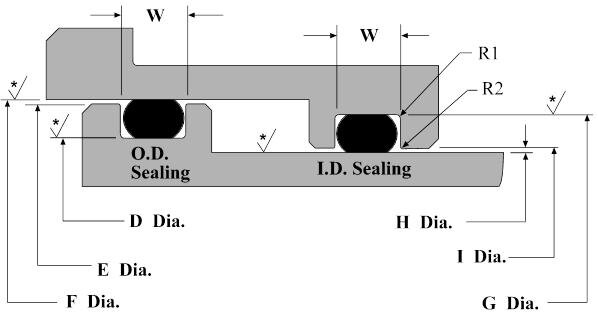

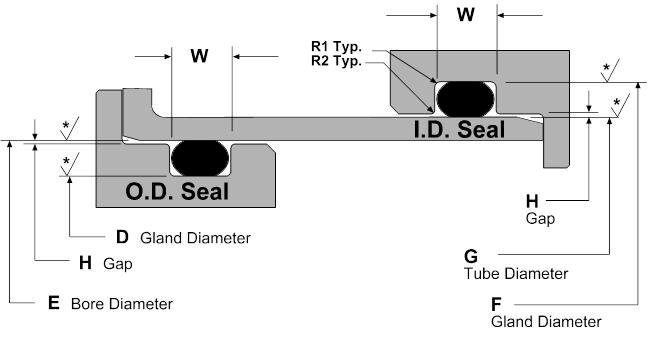

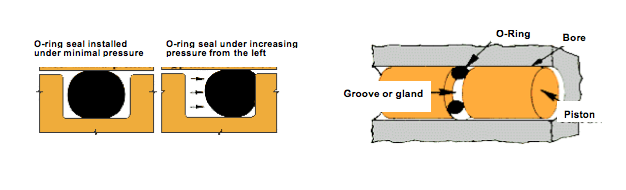

Gland Design for Static Application for Orings with Axial Squeeze Surface Finish X groove top and bottom for liquids X = 32 micro inches (08 μm Ra) • Gland Dimensions Static ApplicationFace Seal GlandsMetric W Oring Cross Section E Gland Depth FBasic Oring Design How Orings Seal An oring acts as a seal by blocking any potential leaching path, of a liquid or gas, between two closely matted surfaces An oring is installed in a machined grooved gland (see gland design for examples) in one of the two surfaces to be sealed As the two surfaces are brought together the orings cross section becomes deformed producing a tightIf the seal ring cons ists of more than one part, replace the full seal ring set Si l a garniture d'étanchéité comp rend plusieurs éléments, remplacer l e tout Pull the cable through the seal ring (5) Faire passer l e câble dans l'anneau antipoussière (5) double mechanical seal, lip seal or Oring seal

Oring groove design guides offer default dimensional guidance on the most basic oring groove design applications The best orings are useless without the right groove design which becomes increasingly important the more demanding the application environment Review the general oring groove design considerations before moving onto the specific oring gland design typeLepu m3n o ring seal design for wholesale for oil SGS,ISO,CE/UL/SGS/ M7N mechanical seal made by lepu seal is a popular seal replacement for eagleburgmann m7n this seal we made is a Self cleaning effect seal, and insensitive to low solids contents, this seal design offer strong flexibility in torque transmissions, and for this seal, Lepu'O' Ring Guide Introduction The 'O' ring, or toroidal seal, is an exceptionally versatile sealing device Applications, ranging from garden hose couplings to aerospace or oil and gas duties, make it the world's most popular volumeproduced seal 'O' rings offer many benefits to designers, engineers, maintenance staff and plant

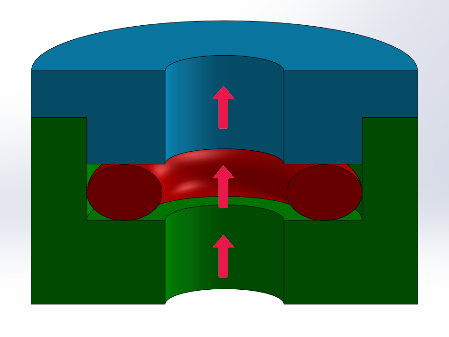

Designing the parts of an application where orings will be applied is broadly termed "oring groove design" In order to seal properly, the oring has to deform in the application by being compressed and stretched in any number of waysThe most common design of mechanical face seals is the oring design This design consists of two symmetrically tapered seal rings and two orings The oring style has two versions, the 7690H which has a ground profile, and the 7697 which has an ascast profile In general, both versions are completely interchangeable At installation, the orings are compressed between the Seal & Design can help with expert staff and a broad wide variety of gasketing products and gasket solutions We fabricate hundreds of materials in different material styles Capabilities include Die cut, Waterjet cut, Beaded Gaskets, Pressure Sensitive Adhesive (PSA) laminated parts, Prototyping, Kiss Cut, custom packaging and kitting, and engineering assistance

Metric O Ring Groove Design Reference Guide

Design Of Oring Seals Design Of Oring Seals

Seal & Design Canada Toronto, Ontario (416) Toll Free email protectedTop Produit o ring seal design pas cher sur Aliexpress France !Group Trelleborg is a world leader in engineered polymer solutions that seal, Design Support and Engineering Tools › ORing Calculator › ORing Calculator The online ORing Calculator offers engineers and professionals a quick and easy way to calculate ORing dimensions and the appropriate housing layout in accordance with the international ORing standard ISO 3601 By

O Ring Groove Design Sealing Australia

Xu S Sealing Theory And Rectangular O Shaped Ring Seals Science Publishing Group

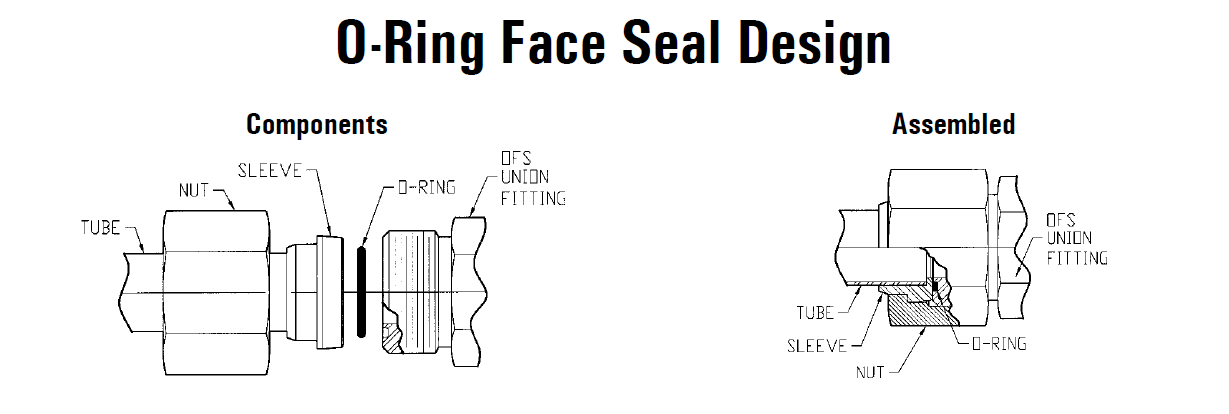

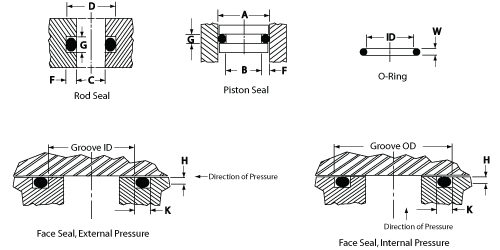

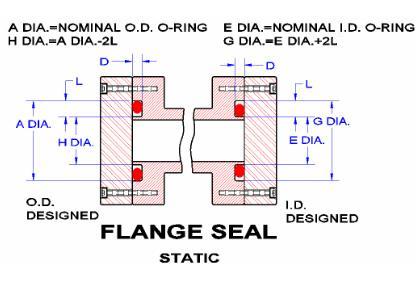

In static seal operating conditions one must not overlook the fact that important variations of pressure and temperature can cause relative movements between the ORing and the surfaces with which it is in contact, and therefore problems of wear and superficial damage that can compromise the seal For this reason it is a good idea to accurately design the ORing's housing seats andORing Handbook Parker Hannifin ORing Diision Europe ORing Handbook Parker Hannifin ORing Diision Europe Preamble Sealing technology by ParkerPrädifa The Engineered Materials Group of the Parker Hannifin Corporation is the worldwide leader in the field of designing, developing and manufacturing sealing systems, vibration dampers, EMI shielding systems and heatThe face seal design chart below explains the hardware dimensions to use for an Oring seal when the groove is cut into a flat surface For designing systems which contain internal pressure, like the example below, the groove's outside diameter (OD) is primary, and the groove's width then determines the inside diameter Conversely, when designing systems which seal equipment from

Jehbco S O Ring Design Articles Jehbco Silicones

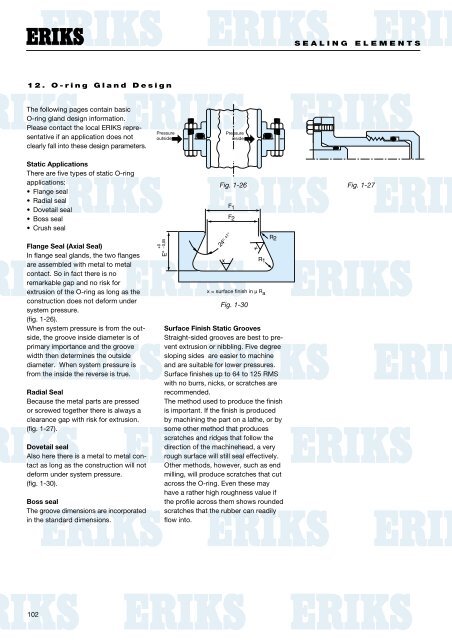

Eriks Technical Manual O Ring Gland Design Information

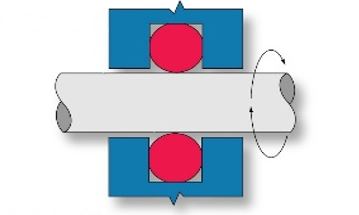

Rotary ORing Seal Gland Click image above to see design charge, table and guide 54 An Oring has proved to be a practical rotary shaft seal in many applications With the correct design, Parker ORing rotary seal compound N, will provide satisfactory service at surface speeds up to 1500 feet per minuteOne general guideline for good Oring application and design is to maintain a range of % sqeeze on the Oring (~1040% for static and no more than 30% for dynamic) No less than 75% of the seal crosssection should be contained within the groove to ensure the seal does not "roll" or extrude out of the grooveSimplicity of housing design The alternative idea of using a guard vacuum outside an Oring seal has been known for many years, the main reason behind it usually being given as the prevention of leaks past the Oring The measurements quoted above suggested that such a technique, by eliminating permeation, should allow very low ultimate pressures, and could form a satisfactory

O Ring Metric Groove Design Seal Design Groove Design Metric

O Ring Inspection Machine At Seal Design Inc Youtube

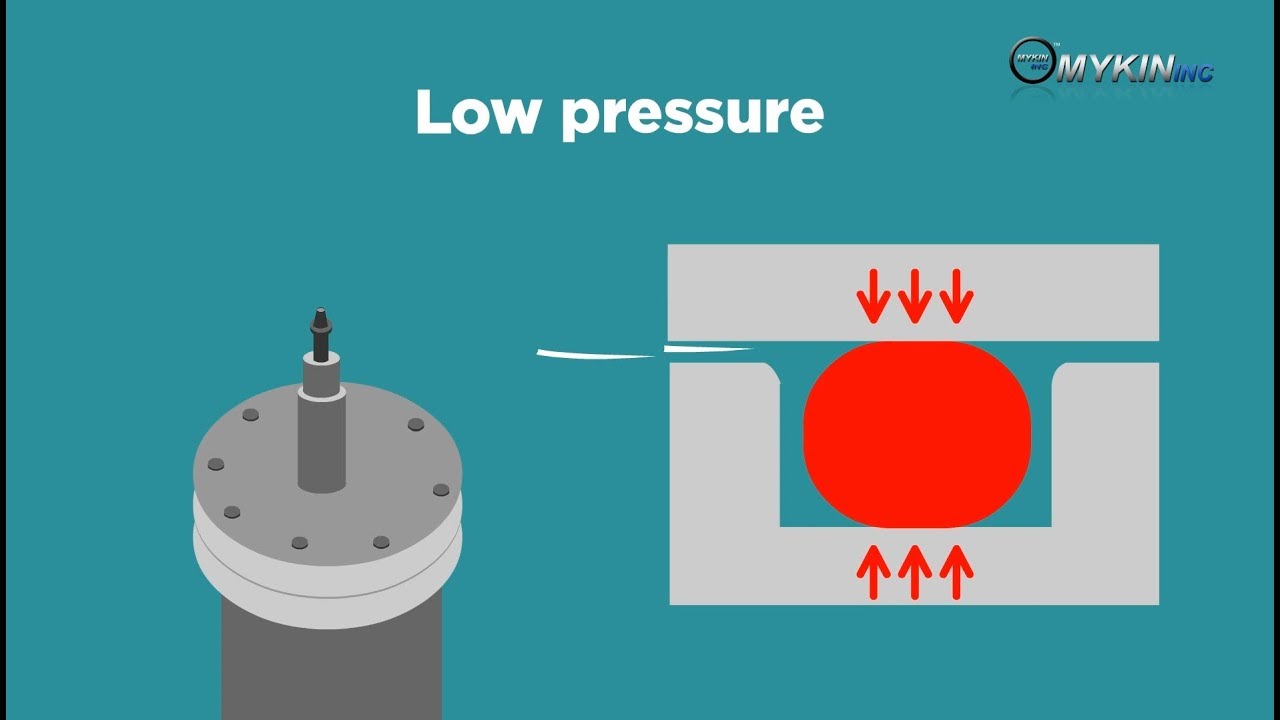

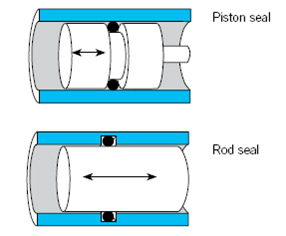

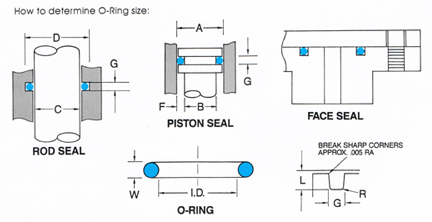

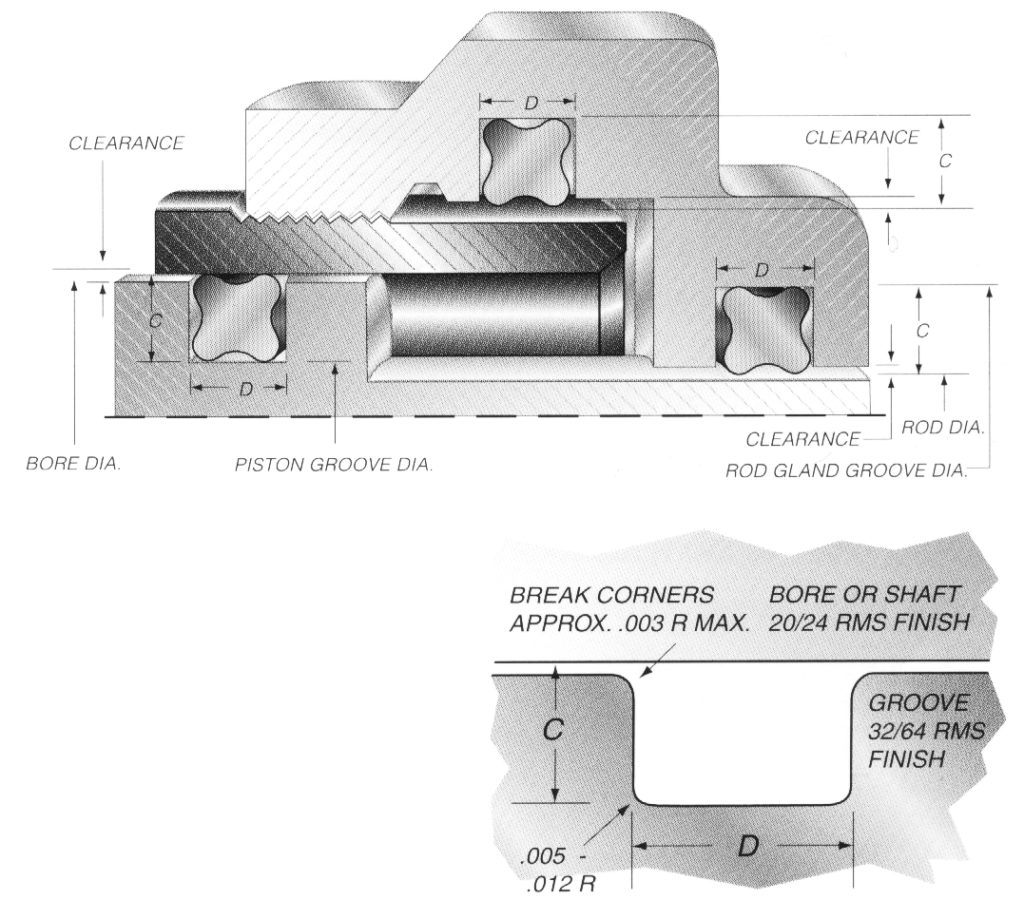

DESIGN DIMENSIONS FOR ORING INSTALLATION Orings are normally used as seals in several ways, and dimensions of the groove or gland will also vary with the cross section of the ring, the type of operation, and the amount of pressure used in the system These dimensions will also be different if the Oring is sealing a liquid which has a low volume Oring and Seal Design Considerations Departments Expert Design Elastomer seals are unlike any other materials that design engineers confront Metal or plastic parts, for instance, are probably failing if visibly distorted But, an Oring must be deformed to function properly In fact, an Oring that is not squeezed and stretched in its application is the wrong Oring Here areO Ring Seal Design Manufacturers, Factory, Suppliers From China, We warmly welcome business partners from all walks of life, expect to establish friendly and cooperative business contact with you and achieve a winwin goal

What You Need To Know About Dynamic Seal Applications Hot Topics

At Discount O Ring Seal Design Spring Customization For Oil Lepu

Orings are the epitome of elegant engineering The ring itself costs only a few cents, and the groove it goes in is simple and easy to manufacture But despWelcome to our Oring Seal Design section This Oring seal design section will give you step by step instructions on how to design a seal or rubber part for your application Consider this a rubber guide or Oring guide in helping you find the exact rubber material and size you need Some parts of this online rubber or Oring design guide can be downloaded in PDF but everything can just beLivraison rapide Produits de qualité à petits prix Aliexpress Achetez malin, vivez mieux

Static Face Or Flange O Ring Seals Designs And Gland Dimensions

What You Need To Know About Dynamic Seal Applications Hot Topics

The ORing seal (8) between the body and the cover, with a protection class of IP 54, ensures This specification covers many aspects to consider in Oring seal design Aerospace recommended Practice ARP1232, ARP1233 and ARP1234 cover Oring gland seal design for the AS568 series Orings These ARP documents containgroove dimensions and stretch and squeeze specifications These specifications are a great starting point for a custom Oring sealBe it dynamic or static operation, radial or axial loading, vacuum or high pressure The following information is a guide for o'ring groove dimensions for both static and reciprocating

Seal Design Store Canada Conception De Rainures De Joints Toriques

Dovetail O Ring Groove Design Guide A Basic Recommendations

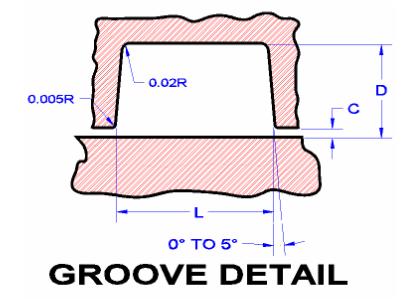

Oring seal The tables at the right and the diagram below provide the recommended gland design parameters In addition, the gland surfaces must be free from all machining irregularities, and the gland edges should be smooth and true and free of nicks, scratches, and burrs A perfectly designed Oring seal is of little use if the OringOring Gland Design Dovetail seal Also here there is a metal to metal contact as long as the construction will not deform under system pressure (fig 130) Boss seal The groove dimensions are incorporated in the standard dimensions Surface Finish Static Grooves Straightsided grooves are best to prevent extrusion or nibbling Five degree sloping sides are easier to machine and areVisit seal and design at wwwsealanddesigncom or at our headquarters located at 4015 Casilio Pkwy, Clarence, NY Seal and Design (716)

Fundamental Of O Ring

O Ring Design O Ring Design Guide O Ring Seal Design Mykin Inc

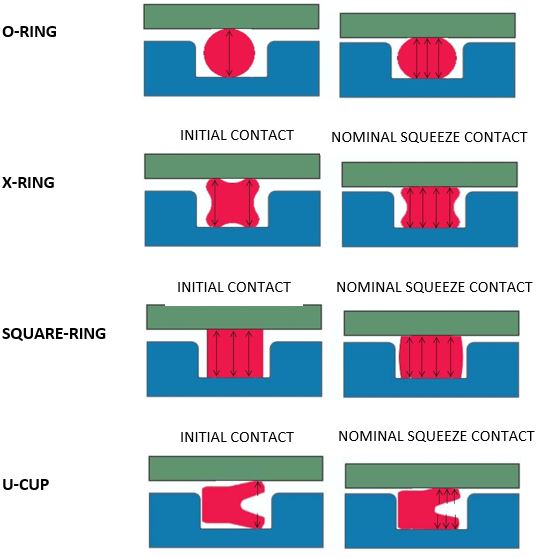

Static and dynamic Oring seal design differs in a few key ways A static Oring is any oring designed to contact with two or more surfaces that do not move relative to one another, whereas a dynamic Oring is one that helps form a seal between moving parts On the whole, static orings are created from less robust and hardwearing materials than their dynamic equivalents It's alsoDesign Chart 42 For Industrial ORing Static Seal Glands 1/2 E Male Gland B1 Dia (B1 Min = A Max 2 L Max) C Dia A Dia Female Gland 1/2 E B Dia D Dia A1 Dia (A1 Max = B Min 2 L Max) Refer to Design Chart 42 (below) and DesignTable 42 for dimensions Finishes are RMS values (e) 0° to 5° (Typ) 6 3 63 R 32 G 1/2 E FL Gland Detail Break CornersDynamic seal design and oring failure modes It also provides an overview of international sizes and standards, and compatibility data for fl uids, gases and solids Engineers in every industry choose orings made by Parker Hannifi n to keep their equipment running safely and reliably That's because Parker's ORing Division, a developer, manufacturer and supplier of precision

1

Oring Ehandbook

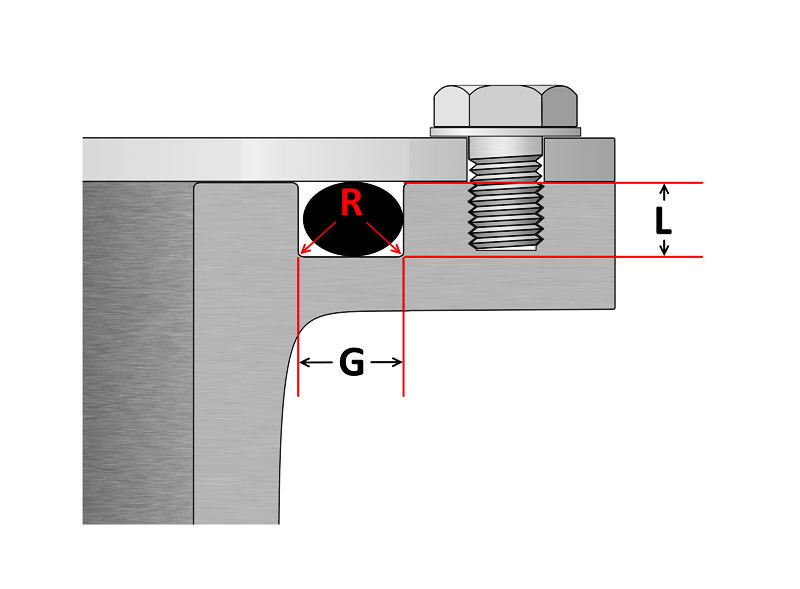

Click here for more information on face seal groove design Note the ORing inside diameter for the next step Calculate the Seal Stretch Using Equation 1, calculate the installed seal stretch If the installed seal stretch is greater than about 3%, you may have to select the next larger ORing or require a custom ORing for your application If you are using an ORing size less than a numberORing design for axial seals is similar to that for radial seals, with the important points summarized below The ORing must be compressed by a predetermined amount, and this compression determines the ORing crosssection diameterWARNING Gland Depth x Groove Width (area of the gland) must be larger than the cross section area of the oring (Pi x R^2)Otherwise many bad things will happen to your design Make sure the squeeze % is sufficiently high enough to seal, but low enough to allow dynamic movements

O Ring Groove Design Global O Ring And Seal

O Ring Groove Design Global O Ring And Seal

Orings are one of the most common seals used in machine design because they are inexpensive, easy to make, reliable and have simple mounting requirements They have been tested to seal up to 5000 psi (35 megapascals) of pressure The maximum recommended pressure of an Oring seal depends on the seal hardness and gland clearance Manufacturing Orings can be produced byThe oring gland design is very simple for face seals Simply cut out a circular groove into one of the plates and leave the other plate completely flat, the groove will have a square/trapezoidal cross section and the dimensions are conveniently already calculated and laid out in tables in the Parker Oring Handbook10 ORING SEALS – THEORY AND DESIGN PRACTICES Theory An oring seal consists of an oring and a properly designed gland which applies a predictable deformation to the oring The gland is basically a groove dimensioned to a certain height "H" and width "W" (Figure 1) to allow a fixed compression of the oring when the gland flanges make metal to metal contact It is also

O Ring Groove Design Standard As568b Seal Design Inc

Static O Ring Face Seal Groove Design Guide

AS568 Oring & gland design utility Oring Piston Seal FastDash TM Oring Piston Seal Design Guide Enter the "A" diameter (ie bore diameter), Press the "Submit" button, The appropriate dash no orings will be listed along with their associated groove details BackUp Rings req'd None 1 2 "A" Diameter inches Oring CrossSection Selections103 in139 in210 in Dash No Act IDAS568B STANDARD ORING GROOVE DESIGN Contact Us For Assistance Or Samples Click Here and contact us today to receive a quote or if you have any questions regarding sizing Dismiss alert The three main types of standard groove designs are Industrial Static also called Radial, Industrial Reciprocating also called Dynamic, and Face Seals also calledStatic oring face seals, used for a wide variety of applications, come in many shapes and forms Whether you need bolted flanges or removable lids, this oring face seal groove design guide will help you choose the right oring for your application ORing Size Charts Oring, xring and square ring size charts

Kumar Rubber Store

Groove Design Gland Design O Ring Groove Gland Design

The tendency of an Oring to return to its original shape when the cross section is deflected is the basic reason why Orings make excellent seals The squeeze or rate of compression is a major consideration in Oring seal design Elastomers may take up the stackup of tolerances of the unit and its memory maintains a sealed condition Orings with smaller cross sections are squeezed Face seals are actually really tricky to get right, because squeezing the Oring requires a great deal of pressure This first lid design is far too thin, and in the middle, there is virtually no squeeze on the Oring, and hence no sealing We can fix this design by adding a lip around the perimeter A third type of design is a boss seal You1 Male or Plug the Oring groove is located on a plug which is inserted into the housing or cylinder (fig 123) 2 Female or Tube the Oring groove is located in the housing or cylinder and a tube is installed through the Oring lD (fig 124) Male or Plug Seal design is based on the following factors (refer to fig 123) Bore Diameter (A)

O Ring Groove Design Sealing Australia

The Zero Leak Plug And Fitting Technology Incorporates A Corresponding Tapered Seal Surface

O Rings Rubber Washers Rubber Gaskets Rubber Mouldings Rubber Extrusion Housing Design

2 Design And Detail Information O Rings Stock O Ring Webshop

On Sale O Ring Seal Design Ring Company For Fluid Static Application Lepu

Fundamental Of O Ring

Diagram Of The Face Seal Design 1 Seal Ring Flexibly Attached 2 Seal Download Scientific Diagram

Seals Eastern End Cap O Ring Seal Design Guideline

For Polaris Utv And Atv Wheel Bearing Tool Double O Ring Seal Design Tools For Repairing Buy On Zoodmall For Polaris Utv And Atv Wheel Bearing Tool Double O Ring Seal Design Tools For Repairing Best Prices Reviews Description

Other Joint Construction Betwen Cooling In Cavity And Mold Base With O Ringo Ring Taizhou Huangyan Mega Mould Co Ltd

American Seal Packing General Design And Gland Dimensions

Untitled Document

Oring Ehandbook

39mm Wheel Bearing Tool Double O Ring Seal Design Fit For Can Am Maverick X3 Max Utv Buy 39mm Wheel Bearing Tool Double O Ring Seal Design Fit For Can Am Maverick X3 Max Utv In Tashkent

Blqldiemjpktem

O Ring Groove Design Seal Design Inc

Oring Ehandbook

Jehbco S O Ring Design Articles Jehbco Silicones

Www Pressureseal Com Orings Oguide Pdf

Http Practicalmaintenance Net Wp Content Uploads Working Design Considerations And Maintenance Of O Rings Pdf

O Ring Wikipedia

Groove Design O Ring Seals Minnesota Rubber Plastics

Dynamic Reciprocating Gland Design Dynamic O Ring Gland

O Ring Gland Design Guide Oringstore Com

O Ring Face Seal Hydraulic Fitting

O Ring Installation Design And Specification Static Flange Application Engineers Edge

Roymech O Ring Seals

O Rings O Yeah How To Select Design And Install O Ring Seals Tarkka

Rotary Seals Design For Construction Machinery Dms Seal Manufacturer

Cost Effective High Performance O Rings Trelleborg

Efunda Introduction To O Rings

4 Common Mistakes In Designing For An O Ring Axial Face Seal Hot Topics

4 Common Mistakes In Designing For An O Ring Axial Face Seal Hot Topics

Oring Ehandbook

How To Design An O Ring Groove Vizeng

Funky O Ring Seal Design Fsf Company For Fluid Static Application Lepu

The Apple Rubber Seal Design Guide Turns 25 Official Apple Rubber Blog

Pin By Angela Schmid On Mechanic S Corner Groove Design Seal Design Groove

Dynamic O Ring Design Chart Marco Rubber Plastics Custom O Rings Supplier

O Ring Groove Design Sealing Australia

Triangular O Ring Grooves Mechanical Seal Engineering Eng Tips

Applications Technology Sealing Elastomers In The Semiconductor Industry Are Used In Hundreds Of Applications Unique Environments Such As Vacuum And Plasma And Demanding Requirements For Contamination Place Great Importance On The

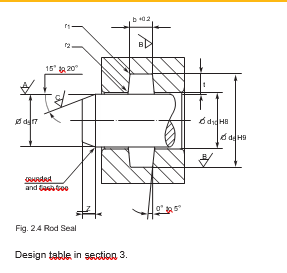

Seals Eastern O Ring Rod Seal Design Guideline

Static O Ring Face Seal Groove Design Guide

Buna O Ring O Ring In Houston And Minneapolis Dichtomatik

O Ring Groove Design

Http Practicalmaintenance Net Wp Content Uploads Working Design Considerations And Maintenance Of O Rings Pdf

Static O Ring Guide Engineering Design Guide For Static Seals

Engineering Seals Static Joint Design With Reinforced Rubbers

Conception Des Rainures Du Joint Torique Daemar Inc Joints Toriques Etancheite Bagues De Retenue Coussinets Caplugs Cales De Support Clefs En Barre

Practical Seal Design Mechanical Engineering Book 29 Martini Ebook Amazon Com

Oring Ehandbook

O Ring Groove Design O Ring Groove Dimensions Mykin Inc

1

Q Tbn And9gcswtjload81k Dl34nzgjq36ct5sp1l5kxm3uysdyopehhdli5w Usqp Cau

O Ring And Seal Design Considerations Today S Medical Developments

Seals Eastern O Ring Rod Seal Design Guideline

1

Sealink Sealing Mechanism Lubricant Free Mechanical Seal Design Sealink

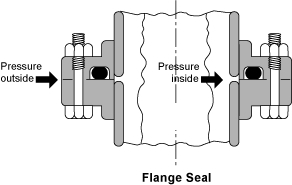

Seals Eastern Flange Seal O Ring Design Guideline

Static O Ring Design Chart Marco Rubber Plastics Custom O Rings Supplier

Ficient Design Static O Ring Groove Design Mechanical Engineering

Hydraulic Cylinder Piston Seals Piston Seals Dms Seal Manufacturer

2 Design And Detail Information O Rings Stock O Ring Webshop

39mm Wheel Bearing Tool Double O Ring Seal Design Fit For Can Am Maverick X3 Max Utv Aliexpress

Gland Design Oringsusa

Customized Viton Quad Ring For Dynamic Seal Manufacturers Suppliers Factory Direct Wholesale Xlong

O Ring Lusida Rubber Products

Seal Design O Ring Design O Ring Design Guide

Back Up Rings O Rings Performance Sealing Inc

Untitled Document

Please Advice On This O Ring Seal Design Mechanical Seal Engineering Eng Tips

China O Ring Seal Design Flat Rubber O Rings Manufacturer China O Ring Cord Stock O Rings Sizes Metric Standard

Dynamic Rotary Gland Design Dynamic O Ring Gland

O Rings An Overview Sciencedirect Topics

Design Of O Ring Seals Ppt Video Online Download

Design Of O Ring Seals Ppt Video Online Download

O Ring Groove Design Global O Ring And Seal

Seal Design O Ring Design O Ring Design Guide

Quad Ring Groove Design Daemar Inc

0 件のコメント:

コメントを投稿